ASTM A182 Alloy Steel F9 Orifice Flanges, Alloy Steel F9 Socket Weld Flanges Manufacturer in India.

Unifit Metalloys Inc is a renowned trader and exporter of AS F9 Flanges, which are in fact used to be straight end pipe or hose in shape. Meanwhile Cr-Mo F9 Slip On Raised Flanges, which is one of the most popular categories in flanges, is a dimension in lengthways of a straight pipe with male strings attached on both the ends. Briefly, Chromium Molybdenum F9 Blind Raised Flanges is a connector or threaded on both the ends. Alloy Steel F9 Spectacle Blind Flanges are manufactured with dissimilar grades of standard ranges and meet its terms through international and national standards.

Table of Contents

- Alloy Steel F9 Flanges Specification

- ASTM A182 Grade F9 Alloy Steel Flanges Equivalent Grades

- Grade F9 Alloy Steel Flanges Chemical Composition

- ASTM A182 Alloy Steel F9 Flanges Mechanical Properties

- Chrome Moly F9 Flanges Types

- Other Types of Grade F9 Alloy Steel Flanges in Stock

- ASTM A182 Cr-Mo F9 Flanges Schedule / Class

- ASME B16.5 Alloy Steel F9 Pipe Flanges Dimensions In MM

- Pressure Rating of Alloy Steel F9 Pipe Flanges

Table D & Table E Alloy Steel F9 Flange, Series A & B Alloy F9 Weld Neck Flange, Alloy Steel A182 F9 Lap Joint Flange, DIN 1.7386 Spectacle Blind Flanges, UNS K90941 Spacer Ring Flanges, Alloy Steel F9 Slip on Flanges, Chrome Moly F9 Long weld Neck Flanges Supplier in Mumbai, India.

Get a best quote for ANSI B16.11 Alloy Steel F9 Flanges from Leading Manufacturer, Buy Grade F9 Chrome Moly Weld Neck Flanges/Slip On Flanges at Best Price in India.

Alloy Steel F9 Threaded Flanges, which is sometimes also called as a service ell or street ell, is a form of piping or plumbing planned to join a piece of pipe to another fitting at a particular angle. CrMo F9 Forged Flanges can be used in sewers, drainage, water supply, vents, central vacuum systems, compressed air and gas lines, sump pump drains, HVAC, and at any place where plumbing fittings would be used to attach parts of pipe. These Alloy Steel F9 Weld Neck Flanges are used among the throng buyers and as well being used all over in different industries. These Chrome Moly F9 Socket Weld Flanges for all the time come in different grades, sizes and classes, making the most required after.

Alloy Steel F9 Flanges Specification

| Specifications | ASTM A182 / ASME SA182 |

|---|---|

| Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| ASME SA 182 Flange | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Flange UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Flange EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Flange Production technique | Forged, Heat treated and machined |

| Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing

AS, ANSI, BS, DIN and JIS |

| ASME A182 Flange Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| ASTM A182 Flange Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Flange Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of Flange | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| ASME SA182 Flange Uses & application | Bitumen upgraders. Heavy oil refineries. Nuclear power (mostly seamless). Petrochemicals and acids. |

| EN 1092-1 Flange Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi & Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

ASTM A182 Alloy Steel F9 Flanges Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | Trade Name |

| Alloy Steel F9 | K90941 | 1.7386 | 9Cr-1Mo |

Grade F9 Alloy Steel Flanges Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F9 | 0.15 max | 0.3-0.6 | 0.5 - 1 | 0.03 | 0.03 | 8 - 10 | 0.9 - 1.1 |

ASTM A182 Alloy Steel F9 Flanges Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| Alloy Steel F9 | 380 | 585 | 20 |

Chrome Moly F9 Flanges Types

ASTM A182 Alloy Steel F9 Weld Neck Flanges

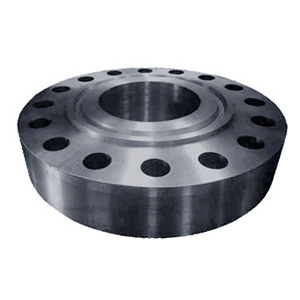

ASTM A182 Alloy Steel F9 Slip-on Flanges

ASTM A182 Alloy Steel F9 Blind Flanges

ASTM A182 Alloy Steel F9 Socket weld Flanges

ASTM A182 Alloy Steel F9 Long Weld Neck Flanges

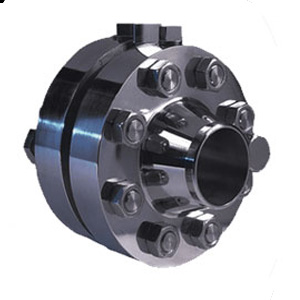

ASTM A182 Alloy Steel F9 Orifice Flanges

ASTM A182 Alloy Steel F9 Lap Joint Flanges

ASTM A182 Alloy Steel F9 Spectacle Blind Flanges

ASTM A182 Alloy Steel F9 Weldo-Nipolet Flanges

ASTM A182 Alloy Steel F9 Ring Type Joint Flanges

ASTM A182 Alloy Steel F9 Groove & Tongue Flanges

ASTM A182 Alloy Steel F9 Reducing Flanges

ASTM A182 Alloy Steel F9 Flanges Manufacturing Standards

| American Steel Flanges Standard | |

| Standard Code | Standard Name |

| ANSI ASME SA-182 | Forged Flanges |

| ANSI ASME B16.5 | Slip on flange, Welding neck flange, Blind flange, Threaded flange, Lap joint flange, RTJ flange |

| ASME – B 16.47 | Welding neck flange, Blind flange |

| ASME – B 16.36 | Welding neck flange Slip on flange |

| German Steel Flanges Standard | |

| DIN 2527 | Steel Blind Flanges, BLRF |

| DIN 2573 / 2576 | Flat Flange for Welding (Slip On) |

| DIN 2673 | Loose Flanges and Rings for Welding (Slip On Flanges and Plain Collars) |

| DIN 2641 / 2642 | Lapped / Loose (Lap Joint) Flanges Plain Collars |

| DIN 28115 | Long Neck Welding Flanges |

| DIN PN10, PN16 | Alloy Steel F9 PN10 Flanges, F9 Alloy Steel DIN PN 10 Flanges, A182 F9 Alloy Steel PN16 Flange |

| DIN PN20, PN25 | Alloy Steel F9 PN20 Flanges, F9 Chrome Moly DIN PN 25 Flanges |

| DIN PN40, PN50 | Chrome Moly Steel F9 PN40 Flanges, F9 Alloy Steel DIN PN 50 Flanges |

| Japanese Steel Flanges Standard | |

| JIS B2220 | Slipon plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) |

| JIS B2291 | Slipon plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) |

| JIS 5K, 10K | Alloy Steel F9 5K SORF Flanges, F9 Alloy Steel 10K SOFF Flanges |

| JIS 16K, 20K | Alloy Steel F9 16K Blind Flanges, A182 F9 Chromium Molybdenum Steel 20K BLRF Flanges |

| JIS 30K, 40K | Alloy Steel F9 30K Slip on Flanges, F9 Alloy Steel 40K Blind Flanges |

| Italian Flanges Standard | |

| UNI FLANGES | Plan flanges (2276, 2277, 2278, 6083, 6084) Welding neck (2280, 2281, 2282, 2283, 2284, 2285, 2286) Lapped flanges (6088, 6089, 6090, 2999, 2300) Blind flanges (6091, 6092, 6093, 6094, 6095, 6096, 6097) threaded flanges (2253, 2254) |

| British Standard Pipe Flanges Standard | |

| BS 10 Table D | Alloy Steel F9 BS 10 Table D Flanges, F9 Table D Pipe Flange |

| BS 10 Table E | Alloy Steel F9 BS 10 Table E Flanges, A182 F9 Table E Pipe Flange |

| BS 10 Table F | Chromium Molybdenum Steel F9 BS 10 Table E Flanges, F9 Cr-Mo Table E Flanges |

| BS 10 Table H | Alloy Steel F9 BS 10 Table E Flanges, Cr-Mo F9 Table E Pipe Flanges |

Other Types of Grade F9 Alloy Steel Flanges in Stock

|

|

ASTM A182 F9 Chrome Moly Flanges Schedule / Class

| Flange Schedule/Class | Pipe Size - Pipe Flanges | Flange Connection Type | Max. Pressure |

|---|---|---|---|

| ASME B16.5 Class 150 | 1/2" | FNPT | 150 psi |

| ASME B16.5 Class 150 | 1/2" | Socket Weld | 275 psi |

| ASME B16.5 Class 150 | 1/2" | Welded | 150 psi |

| ASME B16.5 Class 150 | 3/4" | FNPT | 150 psi |

| ASME B16.5 Class 150 | 3/4" | Socket Weld | 275 psi |

| ASME B16.5 Class 150 | 1-1/4" | Socket Weld | 275 psi |

| ASME B16.5 Class 150 | 1-1/2" | Socket Weld | 275 psi |

| ASME B16.5 Class 150 | 2" | FNPT | 150 psi |

| ASME B16.5 Class 150 | 2" | Socket Weld | 275 psi |

| ASME B16.5 Class 150 | 2-1/2" | Socket Weld | 275 psi |

| ASME B16.5 Class 150 | 3" | Socket Weld | 275 psi |

| ASME B16.5 Class 150 | 4" | FNPT | 150 psi |

| ASME B16.5 Class 150 | 4" | Socket Weld | 275 psi |

| ASME B16.5 Class 300 | 1/2" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 1/2" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 1" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 1" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 1-1/4" | FNPT | 720 psi |

| ASME B16.5 Class 300 | 1-1/4" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 1-1/2" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 1-1/2" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 2" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 2" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 2-1/2" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 2-1/2" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 3" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 3" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 4" | Slip On | 720 psi |

| ASME B16.5 Class 300 | 4" | Slip On | 720 psi |

ASME B16.5 Alloy Steel F9 Pipe Flanges Dimensions

| NPS (in.) |

Alloy Grade F9 Flanges Dimensions | ||||

|---|---|---|---|---|---|

| Dia. of Flange (in.) |

No. of Bolts |

Dia. of Bolts (in.) |

Dia. of Bolt Holes (in.) |

Bolt Circle (in.) |

|

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |

Pressure Rating of Alloy Steel F9 Pipe Flanges

| ASME/ANSI B 16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Slip on Flange, Threaded Flange, Welding Neck Flange, |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Alloy Steel ASTM A182 Grade F9 Flanges Suppliers in India

| City We Supply Flanges | |||||

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Alloy Steel F9 Flanges Exporter in India

| Countries we export Flanges worldwide: | ||||

| Manama | Atyrau | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Russia | Vietnam | Jordan | Portugal | Egypt |

| Morocco | Israel | Costa Rica | Iraq | Madagascar |

| Kazakhstan | Thailand | Romania | Philippines | Spain |

| Hongkong | Taiwan | Japan | Ukraine | Chile |