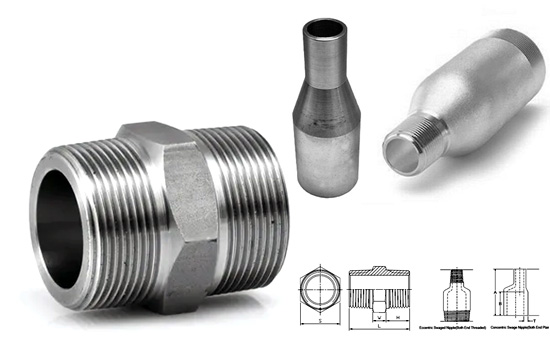

Cupro Nickel Threaded Swage Nipple, Duplex Steel Threaded Hex Head Nipple Manufacturer, Hastelloy Threaded Swage Nipple NPT, Titanium Threaded Hex Head Nipple stockist, Nickel Alloy Threaded Swage Nipple Manufacturer in India.

Jade Special Metals is one of the finest distinguished traders and suppliers of Threaded Hex Fittings & Threaded Swage Nipple Fittings, which is being welded to itself or another alloy from the same sub-set. However, Stainless Steel Threaded Hex Fittings is not suggested for the usage in temperatures in surfeit of 65 degree Celsius. For its applications, Carbon Steel Threaded Swage Nipple Fittings is generally used in Railroad cars, Shipbuilding, Coachwork, Aluminum armor, Pressure vessels, and so on. Super Duplex Steel Threaded Hex Fittings can be manufactured in shortest lead times to meet the rising needs of marine, oil and gas, power generation, paper and pulp manufacturing and general engineering industries. Alloy Steel Threaded Swage Nipple Fittings is an alloy that includes a heat treatable formed alloy most excellent suitable for applications that involves highest electrical conductivity and moderate strength.

ANSI B16.11 Forged Threaded Swage Nipple, BS3799 NPT Threaded Swage Nipple, Alloy Steel Threaded Hex Nipple, DIN 2617 Threaded Hex Nipple Npt, EN10253-2 Threaded Hex Swage Nipple Supplier in Mumbai, India.

Get a best quote for ANSI B16.11 Threaded Nipple from Leading Manufacturer, Buy NPT Threaded Hex/Swage Nipple at Best Price in India.

Inconel Alloy Threaded Hex Fittings can be re-heat-treated to bring back a superior temper for the entire piece. However, the mechanical properties of Monel Alloy Threaded Swage Nipple Fittings depend significantly on the temper, or heat treatment, of the material. Hastelloy Alloy Threaded Hex Fittings is generally used for the building of aircraft structures, such as fuselages and wings, more generally in homebuilt aircraft than commercial or military aircraft. Nickel Alloy Threaded Swage Nipple Fittings is a bit stronger, but is more effortlessly worked and remains resistant to corrosion even when the surface is roughened.

Threaded Hex/Swage Nipple Specification

| Dimensions | ASME B16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

|---|---|

| Size | 1/8” NB to 4” NB |

| Thickness | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Pressure Clas | 3000 LBS, 6000 LBS, 9000 LBS |

| ASME | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN | EN10253-1, EN10253-2 |

| Manufacturer of | Hex Nipple, Swage Nipple |

ANSI/ASME B16.11 Threaded Hex/Swage Nipple Material

| Stainless Steel Threaded Hex/Swage Nipple | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Carbon Steel Threaded Hex/Swage Nipple | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Alloy Steel Threaded Hex/Swage Nipple | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium Threaded Hex/Swage Nipple | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper Threaded Hex/Swage Nipple | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel Threaded Hex/Swage Nipple | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass Threaded Hex/Swage Nipple | 3602 / 2604 / H59 / H62 / etc. |

| Inconel Threaded Hex/Swage Nipple | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 Threaded Nipple |

| Hastelloy Threaded Hex/Swage Nipple | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel Threaded Hex/Swage Nipple | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 Threaded Hex/Swage Nipple | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium Threaded Hex/Swage Nipple | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel Threaded Hex/Swage Nipple | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex Threaded Hex/Swage Nipple | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex Threaded Nipple | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy Threaded Hex/Swage Nipple | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| 254 Smo Threaded Hex/Swage Nipple | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic Threaded Hex/Swage Nipple | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other Threaded Hex/Swage Nipple material | Tin bronze, Alumunum bronze, Lead bronze |

Other Types of NPT Threaded Hex/Swage Nipple in Stock

|

|

ASME B16.11 Threaded Hex/Swage Nipple Dimensions

| ASME B16.11 Forged Threaded Hex Nipple Dimension | |||

| Nominal Diameter | Outside Diameter D |

L(mm) | |

| DN | NPS | ||

| 8 | 1/4 | 13.5 | 60 90 120 150 180 |

| 10 | 3/8 | 17.2 | |

| 15 | 1/2 | 21.3 | |

| 20 | 3/4 | 26.7 | |

| 25 | 1 | 33.4 | |

| 32 | 1.1/4 | 42.2 | |

| 40 | 1.1/2 | 48.3 | |

| 50 | 2 | 60.3 | |

| ASME B16.11 Forged Threaded Swage Nipple Dimension | |||||||||||

| Nominal Pipe Size (NPS) | Outside Diameter | End To End “A” | Wall Thickness | ||||||||

| Large End D1 | Small End D2 | T1 | T2 | ||||||||

| Sch40 (STD) | Sch80 (XS) | Sch160 | XXS | Sch40 (STD) | Sch80 (XS) | Sch160 | XXS | ||||

| 1/4”x1/8” | 13.7 | 10.3 | 57 | 2.2 | 3.0 | 3.7 | 6.1 | 1.7 | 2.4 | ||

| 3/8”x1/8” | 17.1 | 10.3 | 64 | 2.3 | 3.2 | 4.0 | 6.4 | 1.7 | 2.4 | ||

| 3/8”x1/4” | 17.1 | 13.7 | 64 | 2.3 | 3.2 | 4.0 | 6.4 | 2.2 | 3.0 | ||

| 1/2”x1/8” | 21.3 | 10.3 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 1.7 | 2.4 | ||

| 1/2”x1/4” | 21.3 | 13.7 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.2 | 3.0 | ||

| 1/2”x3/8” | 21.3 | 17.1 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.3 | 3.2 | ||

| 3/4”x1/8” | 26.7 | 10.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 1.7 | 2.4 | ||

| 3/4’x1/4” | 26.7 | 13.7 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.2 | 3.0 | ||

| 3/4”x3/8” | 26.7 | 17.1 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.3 | 3.2 | ||

| 3/4”x1/2” | 26.7 | 21.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1”x1/8” | 33.4 | 10.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 1.7 | 2.4 | ||

| 1”x1/4” | 33.4 | 13.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.2 | 3.0 | ||

| 1”x3/8” | 33.4 | 17.1 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.3 | 3.2 | ||

| 1”x1/2” | 33.4 | 21.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1”x3/4” | 33.4 | 26.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/4”x1/8” | 42.2 | 10.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 1.7 | 2.4 | ||

| 1-1/4”x1/4” | 42.2 | 13.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.2 | 3.0 | ||

| 1-1/4”x3/8” | 42.2 | 17.1 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.3 | 3.2 | ||

| 1-1/4”x1/2” | 42.2 | 21.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1-1/4”x3/4” | 42.2 | 26.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/4”x1” | 42.2 | 33.4 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 3.4 | 4.5 | 6.4 | 9.1 |

| 1-1/2”x1/8” | 48.3 | 10.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 1.7 | 2.4 | ||

| 1-1/2”x1/4” | 48.3 | 13.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.2 | 3.0 | ||

| 1-1/2”x3/8” | 48.3 | 17.1 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.3 | 3.2 | ||

| 1-1/2”x1/2” | 48.3 | 21.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1-1/2”x3/4” | 48.3 | 26.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/2”x1” | 48.3 | 33.4 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.4 | 4.5 | 6.4 | 9.1 |

| 1-1/2”x1-1/4” | 48.3 | 42.2 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2”x1/8” | 60.3 | 10.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 1.7 | 2.4 | ||

| 2”x1/4” | 60.3 | 13.7 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.2 | 3.0 | ||

| 2”x3/8” | 60.3 | 17.1 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.3 | 3.2 | ||

| 2”x1/2” | 60.3 | 21.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.8 | 3.7 | 4.8 | 7.5 |

ANSI B16.11 Threaded Hex/Swage Nipple Suppliers in India

| City We Supply Threaded Hex/Swage Nipple | |||||

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Threaded / Screwed Nipple Exporter in India

| Countries we export Threaded Hex/Swage Nipple worldwide | ||||

| Manama | Atyrau | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Russia | Vietnam | Jordan | Portugal | Egypt |

| Morocco | Israel | Costa Rica | Iraq | Madagascar |

| Kazakhstan | Thailand | Romania | Philippines | Spain |

| Hongkong | Taiwan | Japan | Ukraine | Chile |